The automotive industry is moving faster than ever, and at the center of this innovation lies the powertrain, the system that delivers power from the engine to the wheels. For a Philadelphia, PA auto repair shop, understanding emerging technologies that shape powertrain design and performance is essential to providing top-tier service. These advancements are changing how vehicles operate, improving fuel efficiency, reliability, and sustainability across every make and model.

At Schafer’s Auto Center, we stay informed about new technologies so our technicians can deliver the best solutions for every driver. From hybrid systems to advanced materials, the latest trends are helping automakers and repair professionals alike improve performance while reducing emissions. Here are some of the most promising powertrain technologies shaping the future of the industry.

Electrified Powertrains

Electric and hybrid systems are now central to modern vehicle design. Electrified powertrains combine electric motors, batteries, and internal combustion engines to maximize efficiency and performance. These systems reduce fuel consumption and emissions while maintaining smooth acceleration and power delivery. For repair professionals, understanding battery management systems and electric drive components has become as important as traditional engine maintenance. As adoption grows, shops must continue to develop diagnostic and repair expertise for both hybrid and fully electric vehicles.

Advanced Transmission Systems

Today’s transmissions are far more sophisticated than those of previous generations. Many vehicles now use continuously variable transmissions or dual-clutch systems to deliver seamless power transfer and better fuel economy. Some automakers are also incorporating electronically controlled gear-shifting systems that adjust instantly to driving conditions. These technologies improve efficiency and provide smoother acceleration. For technicians, maintaining these systems requires precise calibration tools and up-to-date knowledge of electronic controls.

Lightweight Materials and Design Efficiency

Reducing vehicle weight is one of the most effective ways to improve powertrain efficiency. Advances in materials science have introduced lighter yet stronger components made from aluminum alloys, carbon fiber composites, and high-strength steel. By lowering overall weight, engines require less energy to achieve the same performance levels, enhancing both speed and fuel economy. Repair facilities are adapting to work with these new materials, which often require specialized tools and repair techniques.

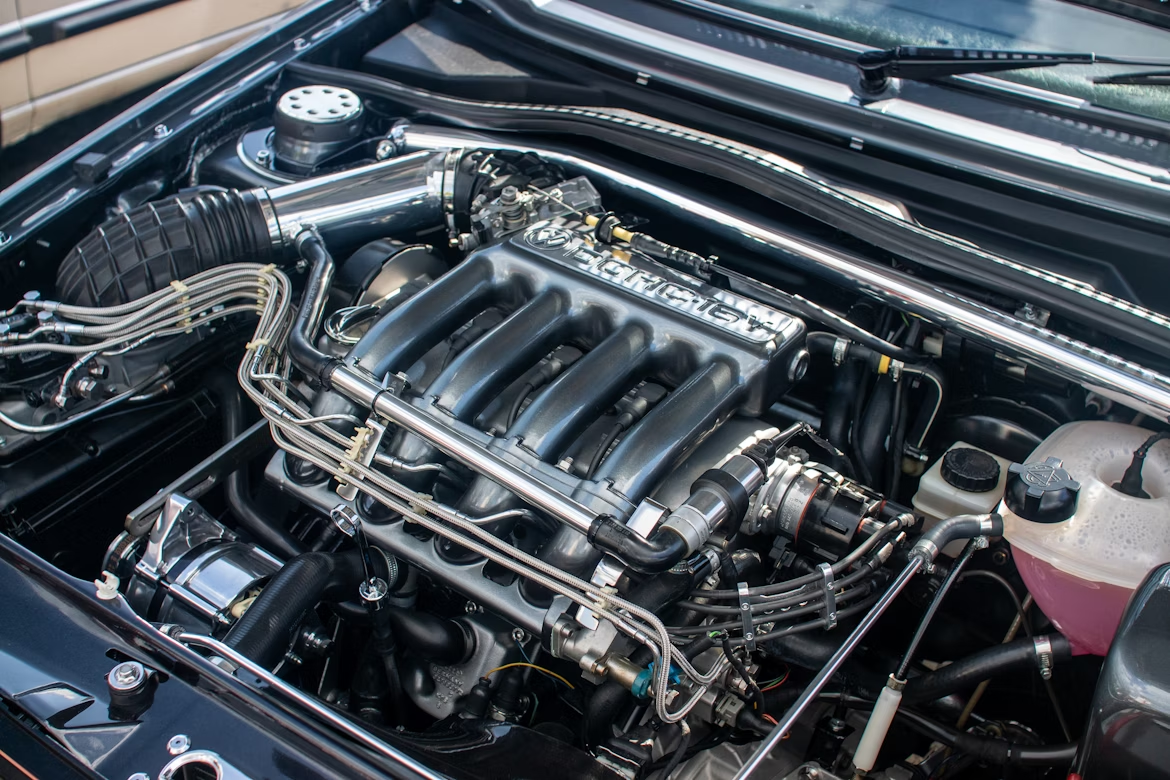

Turbocharging and Engine Downsizing

Modern engines are delivering more power from smaller displacements thanks to turbocharging technology. By compressing air into the combustion chamber, turbochargers increase efficiency and performance without increasing engine size. Many new vehicles now feature smaller, turbocharged engines that achieve the same output as older, larger engines while using less fuel. This trend has made it essential for repair shops to understand proper maintenance for turbo systems, including lubrication, cooling, and airflow management.

Hybrid Drive Components and Regenerative Systems

Hybrid systems are no longer exclusive to high-end or eco-focused models. They are becoming mainstream across all vehicle categories. Regenerative braking, which converts kinetic energy into electricity during braking, has revolutionized energy recovery. This technology not only improves fuel efficiency but also extends the life of braking components. As these systems evolve, repair technicians must be skilled in both mechanical and electrical diagnostics to ensure seamless integration between regenerative and conventional components.

Smart Engine Management and Predictive Controls

Modern vehicles rely heavily on digital sensors and control units that manage engine performance with incredible precision. These systems use real-time data from multiple sensors to optimize fuel injection, air intake, and timing. Predictive engine controls can even learn a driver’s habits and adjust performance for efficiency or responsiveness. For repair professionals, this means adopting diagnostic equipment that can communicate effectively with a vehicle’s onboard computer systems. Understanding how software interacts with hardware is now a critical part of powertrain maintenance.

Alternative Fuels and Sustainable Power Options

Beyond gasoline and diesel, alternative fuels are gaining traction as part of the global push toward cleaner energy. Biofuels, hydrogen, and synthetic fuels are being explored as sustainable options for internal combustion engines. Each presents unique benefits and challenges, including storage, efficiency, and compatibility with existing systems. While widespread adoption may still be developing, forward-thinking shops are already preparing for these transitions. Staying knowledgeable about these energy sources ensures readiness for whatever fuel technologies dominate the next decade.

As powertrain technology continues to evolve, repair professionals must adapt to keep pace. The industry is shifting toward smarter, cleaner, and more efficient systems that require both traditional mechanical skill and advanced technical understanding. At Schafer’s Auto Center, we make it our mission to stay ahead of these changes so our customers receive expert care, no matter what powers their vehicles. Whether you drive a hybrid, turbocharged, or conventional model, a Philadelphia, PA auto repair shop equipped with modern tools and training can help you keep it running at peak performance. Schedule maintenance or repairs now to ensure your vehicle’s powertrain is ready for the future of driving.